What are Nxburst™ Safety Cartridges?

Nxburst™ is a non-detonating blasting technology used to break rock and concrete. Designed as a safe alternative to traditional explosives, Nxburst™ Rock Breaking Safety Cartridges are used in a wide range of construction, demolition, mining, and quarrying environments. The cartridges do not produce a destructive shock wave like detonating explosives. Instead, Nxburst™ propellant-based cartridges produce a controllable pressure wave that limits airblast overpressure, flyrock, noise, dust, and vibrations. This makes Nxburst™ suitable for breaking rock and concrete in environmentally sensitive areas.

What are the advantages of using Nxburst™ Safety Cartridges?

Nxburst™ Rock Breaking Safety Cartridges are much safer to handle, transport, and store than traditional explosives. Unlike detonating explosives, Nxburst™ cartridges pose no significant hazard in their packaged state. Furthermore, the Nxburst™ method of breaking rock and concrete allows a controlled approach to blasting. Below is a list of advantages of using Nxburst™ Safety Cartridges.

- Nxburst™ cartridges produce very low overall airblast pressure levels compared to conventional explosives. Airblast pressure is the pressure produced by blasting.

- Nxburst™ cartridges also produce lower noise levels compared with blasting using conventional explosives.

- Nxburst™ cartridges generate limited vibrations that are well within most imposed restrictions for rock breaking close to sensitive structures.

- Nxburst™ cartridges produce a negligible level of noxious gases that can be cleared quickly with adequate airflow.

- Nxburst™ cartridges also result in a minimal quantity of low velocity flyrock (<10m) due to controlled gas release from the cartridges.

Additionally, Nxburst™ Rock Breaking Safety Cartridges only require localized clearance of equipment and personnel instead of compete site evacuation. This means rocks and concrete can be broken in close proximity to working operations. All of these properties give Nxburst™ a huge advantage over traditional blasting technologies, especially in environmentally sensitive areas.

How do Nxburst™ Rock Breaking Safety Cartridges work?

Nxburst™ Safety Cartridges are filled with a propellant compound. Once ignited, a Nxburst™ cartridge produces a high volume of harmless gas, mainly nitrogen, carbon dioxide, and steam. The gas produced fractures the rock or concrete. Unlike conventional explosives that detonate, Nxburst™ Safety Cartridges deflagrate. In other words, the propellant burns steadily at a rate determined by the confining structure. When the cartridge is sealed in a drill hole in a rock, the gas produced from ignition enters micro-fractures in the rock created by drilling. The gas also enters into the natural fractures and areas of weakness of the rock. This initiates shearing, or splitting, of the rock.

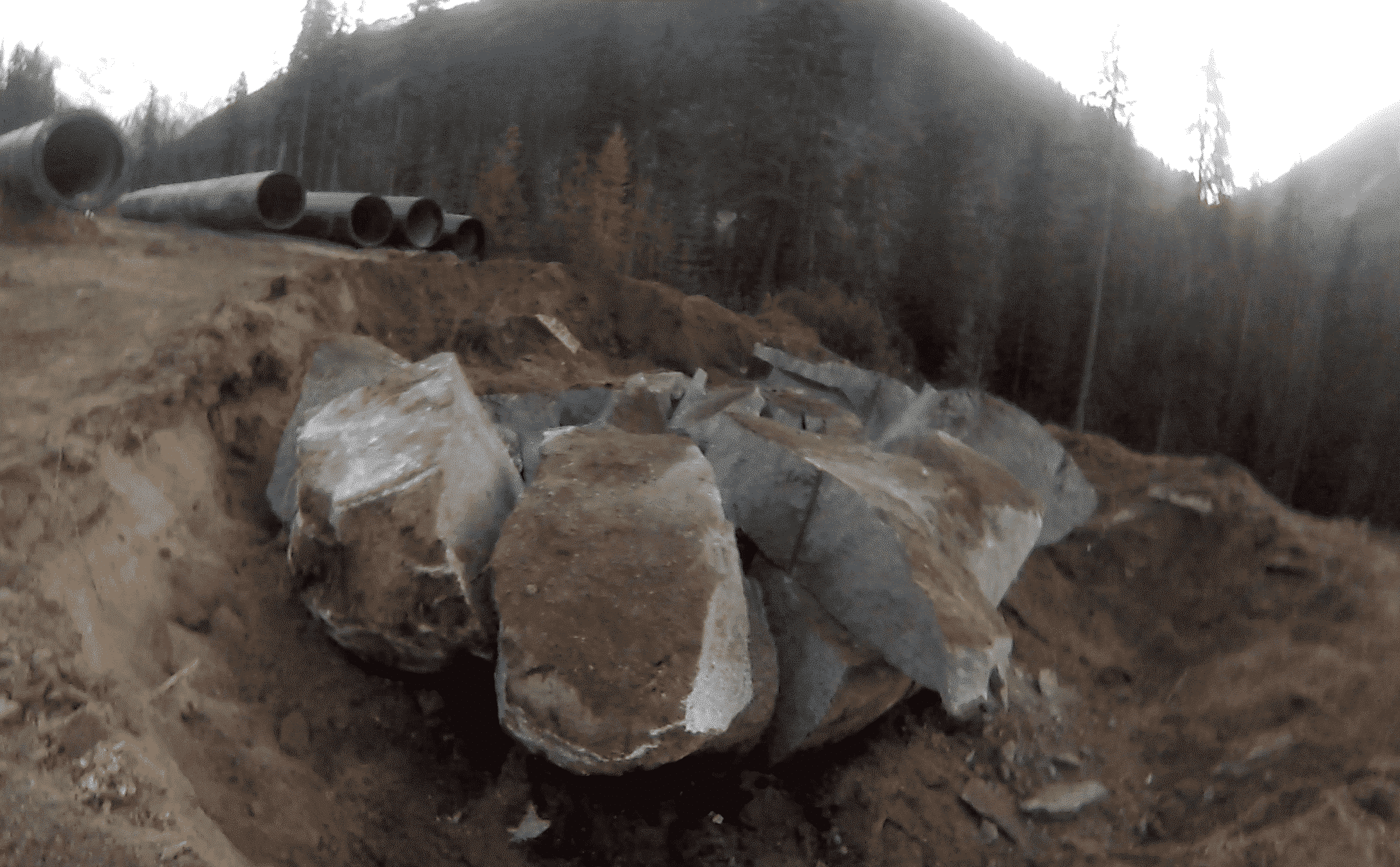

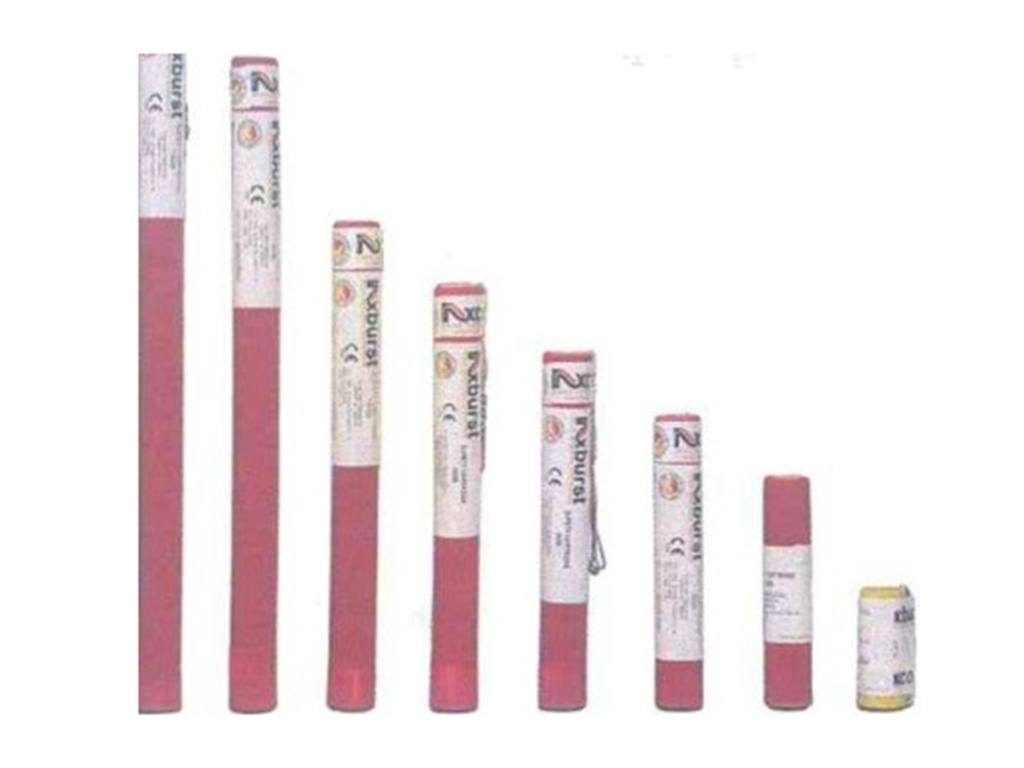

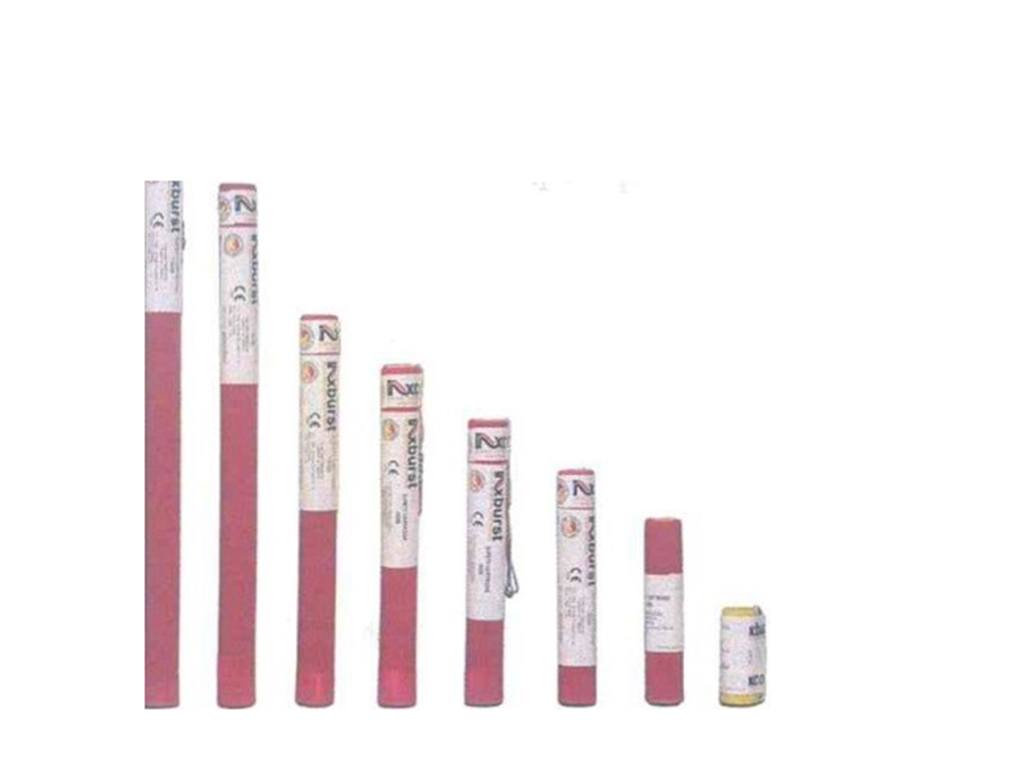

Which rock breaking applications use Nxburst™ Rock Breaking Safety Cartridges?

Nxburst™ Rock Breaking Safety Cartridges are used in a wide variety of rock breaking applications, including: small boulders, small demolition, armour stone splitting, concrete demolition, medium-large boulders, swimming pools, dimension stone quarrying, sensitive rock breaking, tunnel enlargement, trenching, sensitive excavation, large excavations, mass excavations, large foundation excavation, sensitive civil rock breaking, and underwater rock breaking.

What are the transport and storage requirements for Nxburst™ Safety Cartridges?

The Nxburst™ cartridge is classified as a 1.4S product under the United Nations (UN) Classification of Hazardous Substances. This is the same category as small arms ammunition. This classification is given to products that do not explode when ignited in their original packaged state. As such, the classification defines Nxburst™ as a non-explosive product for transport and storage purposes. The UN classification system is used by most countries of the world to classify hazardous products according to the danger that each of the products poses while in storage and transport. A UN accredited testing agency tested the Nxburst™ cartridge and subsequently classified it under UN 1.4S as a “Cartridge Power Device.”

What’s the difference between detonation and deflagration?

Detonation and deflagration are both combustion processes, but they have some important differences. Combustion, or burning, is a process by which energy is released. If the combustion process moves outward at a speed slower than sound, or at subsonic speeds, it’s called a deflagration. A deflagration is a controlled way to release energy. If the combustion moves outward at a speed faster than the speed of sound, or at supersonic speeds, it’s called a detonation. A detonation is accompanied by a shock wave and often produces violent destruction. Nxburst™ Rock Breaking Safety Cartridges harness the power of deflagration to break rock and concrete.

What’s the difference between a high explosive and a low explosive?

A high explosive burns at a very rapid rate and detonates instantaneously. It produces gaseous and solid products as a result. A low explosive has combustible materials that burn at a slower rate compared to high explosives, producing a large volume of gas. The rate of burning depends on several factors, such as combustion gas pressure, grain size and form, and composition. Low explosives do not normally detonate.

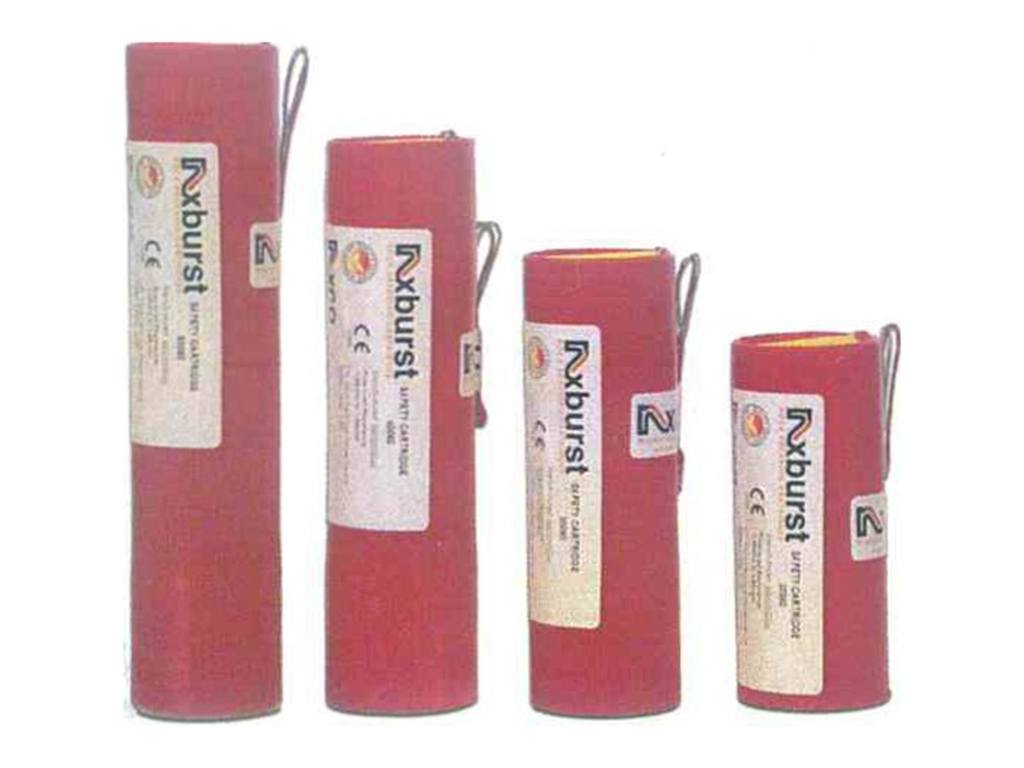

What does a Nxburst™ Safety Cartridge consist of?

A Nxburst™ Rock Breaking Safety Cartridge is made of six components:

- Lead wires

- Tube

- Top end cap

- Electric fuse head

- Propellant and oxidizer mixture

- Bottom end cap

What is the procedure for using a Nxburst™ Safety Cartridge?

Nxburst™ Rock Breaking Safety Cartridges are simple to use. They do not require expensive initiation systems or special tools. Below is the process for using Nxburst™ Rock Breaking Safety Cartridges.

- Drill a hole in the rock or concrete to a depth of 70% of the size of the rock or concrete.

- Insert the cartridge into the hole.

- Stem the hole with stone screening or aggregate.

- Tampen to create a solid seal that will contain the gas when the cartridge is ignited.

- Clear the local area.

- Connect and initiate the cartridge.

Once the Nxburst™ cartridge is initiated, the pressure created by the gas will exceed the tensile strength of the rock or concrete, causing the rock to fracture.